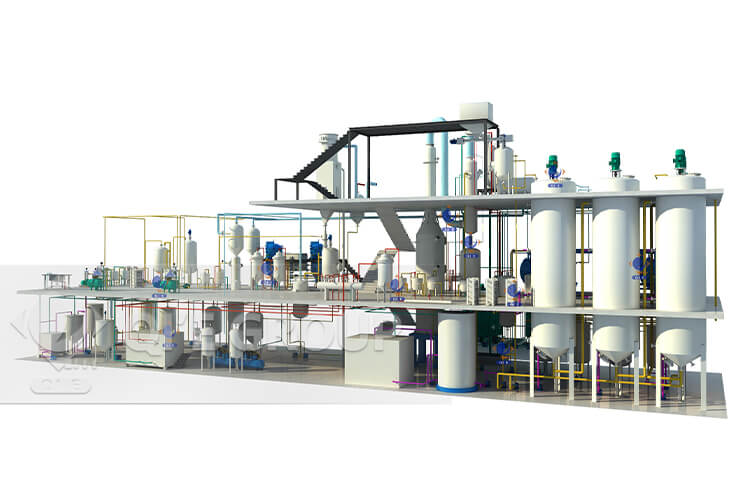

Petroleum fractionation equipment

When you choose Penguin Group's oil fractionation equipment, you not only choose efficient and advanced technology, but also get the opportunity to transform your production line into a strong profit center. Our equipment uses advanced crystallization and precision separation processes to ensure optimal vegetable oil fractionation when producing high-quality palm oil products. At the same time, our customized solutions, with flexible production capabilities ranging from 1 ton to 500 tons per day, ensure that whether you are a small studio or a large manufacturer, you can find products that meet your needs. Our professional team will provide one-stop technical support and services to ensure a good return on your investment. Investing in Qie petroleum fractionation equipment is a wise choice towards sustainable development and market leadership.